The Stihl MS290 chainsaw has been a workhorse around homes and farms for years. Known for its power and reliability, the MS290 is a great choice for cutting firewood, clearing land, or general property maintenance.

But what spark plug does the Stihl MS290 use?

The Stihl MS290 chainsaw’s recommended spark plug is the NGK BPMR7A, selected for meeting Stihl’s specific requirements, durability, and high-quality construction.

The NGK BPMR7A Spark Plug is AVAILABLE HERE ON AMAZON

What Spark Plug Does a Stihl MS290 Take?

The NGK BPM7A is the preferred spark plug for the Stihl MS290 Chainsaw due to its correct specifications, quality, and durability. This spark plug is designed to withstand high heat and combustion pressure, making it an ideal fit for the MS290.

In addition to its durability, the NGK BPM7A also promotes peak efficiency in the chainsaw’s performance. The spark plug’s design allows for a cleaner and more complete combustion process, resulting in improved fuel economy and increased power output.

This means that the Stihl MS290 will run smoother, use less fuel, and have an overall better performance with the NGK BPM7A spark plug installed.

NGK BPMR7A Spark Plug Cross Reference

| Brand | Model Numbers |

|---|---|

| ACDelco | CS42S |

| Autolite | 2974, 2976, 2984, XST2974 |

| Beru | 14SR-5F, 14SR-6F, Z260 |

| Bosch | 0242240506, 0242240576, 0242245533, WS8F, WSR5F, WSR6F, stk 7543 |

| Brisk | 3022, 3130, 3159, PR15Y, PR17YC |

| Champion | 852, CJ8Y, RCJ6Y, RCJ7Y, RCJ7YT04, RCJ7YW24, stk 848, stk 852, stk 859 |

| Denso | 6043, W20MP-U, W22MPR-U, W22MPRU, stk 6023 |

| Dolmar | 965603021 |

| Electrolux | 503235111 |

| General Motors | 5613726 |

| Honda | 98073-57944 |

| Husqvarna | 503235111 |

| Kawasaki | 920702107, E920702107 |

| Kioritz | A425309-0210, A425309-0211, A425309-0301 |

| Motorcraft | A22NX, A42N, stk 107 |

| NGK | stk 4626 |

| Oregon | OPR15Y |

| PAL (Brisk) | PR15Y |

| Tanaka | 018-11610-21, 668-5782 |

| Torch | L7RTC, L8RT |

| Yamaha | 90793-20098 |

NGK BPMR7A Detailed Specifications

| Specification | Detail |

|---|---|

| Shell | |

| Thread Diameter | 14mm |

| Thread Pitch | 1.25mm |

| Seat Type | Gasket |

| Reach | 9.5mm (3/8″) |

| Hex Size | 3/4″ (19mm) |

| Terminal Type | Removable Nut |

| Overall Height | Bantam |

| Gap | .028″ (0.7mm) |

| Center Electrode | |

| Material | Nickel |

| Type | Standard |

| Size | 2.5mm |

| Projection | Projected |

| Ground Electrode | |

| Material | Nickel |

| Type | Standard |

| Quantity | 1 |

| Specifications | |

| Resistor | Yes |

| Resistor Value | 10k Ohm |

| Heat Range | 7 |

| Torque Specs | |

| Cast Iron | 18-25.3 lb. ft. |

| Aluminum | 18-21.6 lb. ft. |

Installation Guide

The installation of a spark plug in the Stihl MS290 is a relatively simple process that can be completed by following these steps:

Installation of a Spark Plug in the Stihl MS290

Tools Needed:

- Spark plug wrench or suitable socket wrench

- Gap gauge (optional if gap adjustment is needed)

Steps:

- Ensure Safety:

- Make sure the chainsaw is turned off.

- Allow the engine to cool if it was recently used.

- Disconnect the spark plug boot/cap.

- Remove Old Spark Plug:

- Use the spark plug wrench to carefully unscrew and remove the existing spark plug from the chainsaw.

- Inspect and Prepare New Spark Plug:

- Check the new spark plug for any damage. Sometimes, new spark plugs can be damaged in shipping.

- Verify the gap matches the specification for the MS290 (usually around 0.02 inches or 0.5 mm, but check the user manual for exact measurements).

- Adjust the gap if necessary using a gap gauge.

- Install New Spark Plug:

- Hand-thread the new spark plug into the socket to avoid cross-threading.

- Once hand-tightened, use the spark plug wrench to snug the spark plug. Be careful not to over-tighten, as this can damage the threads or the spark plug.

- Reconnect Spark Plug Boot/Cap:

- Firmly reattach the spark plug boot/cap onto the new spark plug.

- Ensure it’s securely in place.

- Check and Test:

- Double-check that everything is reassembled correctly.

- Start the chainsaw to ensure it’s running smoothly.

Tips:

- Always use the spark plug recommended by the manufacturer for optimal performance.

- Regularly cleaning and changing the spark plug can improve engine efficiency and longevity.

- If you’re unsure about the gap specification or installation, consult the Stihl MS290 user manual or a professional.

Maintaining Your Spark Plug

Regular maintenance of your spark plug is crucial for the smooth and efficient operation of your engine, whether it’s in a car, lawnmower, or any other machine.

A well-maintained spark plug ensures optimal combustion, contributing to the longevity and reliability of your engine. Here’s how you can keep your spark plug in top condition:

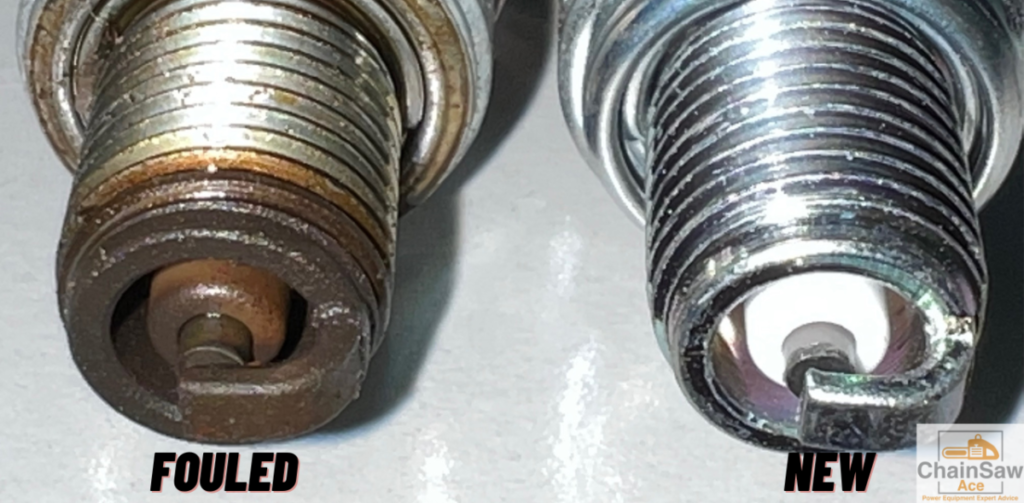

Regular Inspection

- Visual Check: Regularly inspect the spark plug for signs of wear or damage. Look for any cracks in the porcelain and ensure the metal is not corroded or excessively worn down.

- Check the Gap: Use a feeler gauge to check the gap between the electrodes. Incorrect spacing can lead to engine misfires, poor fuel economy, and reduced power.

Cleaning

- Removing Deposits: Carbon deposits can accumulate on the spark plug over time, leading to poor performance. Gently clean the plug with a wire brush or spark plug cleaner, taking care not to damage the electrodes.

- Checking the Electrodes: If the electrodes are worn out or damaged, it’s time to replace the spark plug. Otherwise, uneven wear can lead to inefficiency and engine damage.

Proper Gapping

- Adjusting the Gap: If the gap doesn’t meet the manufacturer’s specifications, adjust it by gently bending the ground electrode. Be careful not to apply too much force, as this can break the electrode.

- Consistent Measurements: Always double-check the gap after adjustment to ensure it meets the required specifications.

Installation

- Correct Torque: When reinstalling the spark plug, make sure to torque it to the manufacturer’s specifications. Over- or under-tightening can lead to engine damage.

- Sealing Properly: Ensure the spark plug is seated properly to avoid any combustion leaks.

Timing for Replacement

- Follow Manufacturer’s Guidelines: Regularly replace your spark plugs according to the schedule recommended by the manufacturer.

- Performance Check: If you notice a decline in engine performance, fuel efficiency, or if the engine starts to misfire, check the spark plugs as they might need replacement.

Additional Tips

- Use the Right Tools: Always use a spark plug socket and wrench for removing and installing spark plugs to avoid damage.

- Engine Health: Remember, the condition of your spark plug can also indicate the health of your engine. Oil or soot buildup can signal other engine problems.

Maintaining your spark plug is not just about preserving the plug itself; it’s about ensuring the health and efficiency of your entire engine.

Regular checks and maintenance can save you from costly repairs and keep your engine running smoothly for years to come.

Wrapping Up

Choosing the right spark plug and maintaining it properly is key to the performance and longevity of your Stihl MS290 chainsaw. The NGK BPMR7A spark plug, with its durability and efficiency, is an excellent choice for ensuring your chainsaw runs at peak performance.

By following the detailed installation guide and maintenance tips provided, you can ensure that your spark plug remains in optimal condition, thereby enhancing the overall health of your chainsaw’s engine.

Remember, regular maintenance isn’t just about immediate performance benefits; it’s an investment in the longevity and reliability of your equipment.

By keeping an eye on the condition of your spark plug and replacing it when necessary, you can avoid many common engine problems and ensure your Stihl MS290 continues to be a reliable tool for all your cutting needs.

Whether you’re clearing land, cutting firewood, or performing general property maintenance, your Stihl MS290 is a powerful ally. Take care of it with the right spark plug and regular maintenance, and it will serve you well for many years to come.

Keep your chainsaw’s engine running smoothly, efficiently, and powerfully, ensuring that every cut is as good as the first.