Chainsaws are power tools that undergo extreme conditions and do require parts to be replaced from time to time. One particular part of the chainsaw that undergoes the most strenuous work is the guide bar and chain. The friction of the guide bar and the chain is reduced by the chainsaw’s oiler but over time they still wear out and need to be replaced.

When you need to replace your chainsaw’s guide bar and chain the quickest and most accurate way is to simply get the part number off the bar. The chain that fits the bar will also be listed in the same area where the guide bars number is located.

If for some reason you can find the part number on the bar and you do not know the model number of your chainsaw you will need to know how to measure the length of the guide bar along with some additional information and what chain fits it.

To measure the length of a chainsaw bar you will need to measure from the point where the guide bar inserts into the chainsaw all the way to the tip of the bar. This measurement is typically done in inches and rounded to the nearest round number. This is the effective length of the guide bar and it’s the number you are looking for if you’re trying to find the length of your bar.

Finding the effective length of the guide bar is only part of the information you need when replacing your guide bar. You also need to know the pitch (if your bar has a sprocket tip), gauge, and whether the oiler port on the guide bar matches up to the oiler port on the chainsaw.

| Guide Bar and Chain Pitch | Guide Bar and Chain Gauge |

| 3/8 Low Profile | .043, .050 |

| .325 | .050, .063 |

| 3/8 Regular | .050, .058, .063 |

What Does the Pitch of a Guide Bar Mean?

The pitch is the distance between drive links on the chain and only applies if your guide bar has a sprocket on the tip. If your bar does not have a sprocket you can ignore the pitch as it relates to the bar and chain however you need to make sure it matches the pitch on your chainsaws sprocket. If your bar does have a sprocket and you cant read the pitch directly off the bar you will need to determine the pitch.

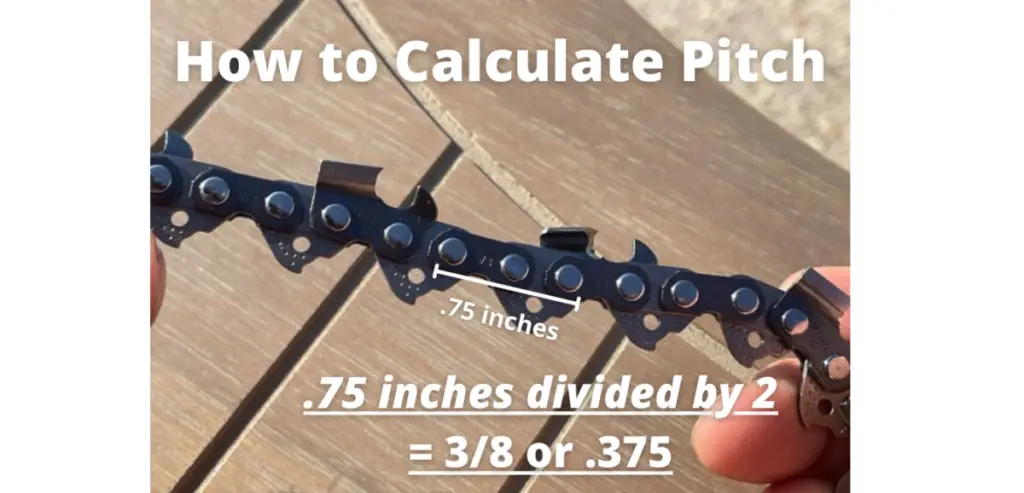

The pitch of the bar is determined by getting measurements from the chain of the saw. The method for determining the pitch is calculated by measuring the distance of any 3 drive link rivets in a row then dividing the number by 2. The resulting number is the pitch of the chain and by extension the pitch of the guide bar as well. Typical pitches are 1/4, .325, and 3/8.

If the pitch of the chain, guide bar, and chainsaws sprocket are not correctly matched the chain will not rotate properly. Always make sure you have the correct pitch.

What Does the Gauge of a Guide Bar Mean?

The gauge of the guide bar is the width of the slot that the chains fit into on the guide bar. If you can not read the gauge of the bar and chain directly from the bar you will need to calculate it. The method of determining the gauge is calculated by measuring the width of the chain’s drags, the part of the chain that fits into the bars slot. This number is represented in thousandths of an inch. Typical gauges are .043, .050, and .063. The thicker the gauge the stronger the chain.

If the chain and guide bar are not matched up correctly, either the chain will not fit into the bar at all or will be floppy loose in the guide bars slot. Always make sure to match your guide bar and chain gauge properly.

Why Match Bar Oil Intake Port and Chainsaw Oil Output Port?

Determining the length, pitch, and gauge of your chainsaw’s guide bar is vital to select the correct guide bar and chain for your chainsaw. However, another very important thing to remember is making sure the oil intake port on the guide bar lines up with the oil output port on the chainsaw.

If these two ports do not line up properly the bar and chain will not receive the required lubrication to keep them cool and rotating freely.

If the bar and chain do not receive lubrication, (bar oil), they will get extremely hot. The heat will cause the chain to seize in the guide bar and possibly destroy the sprocket tip in the guide bar. Once this happens the guide bar and chain will need to be replaced again.

Don’t make the mistake of ruining a new guide bar and chain by forgetting about the oiler ports. The guide bar and chain need lubrication and are useless without oil. A properly lubricated bar and chain can last for a significant amount of time where an under oiled bar and chain will only last for a couple of minutes.

Can you put any length bar on a chainsaw?

There may be some instances where you determine the length, pitch, and gauge of your chainsaw’s guide bar but decide you may want to use a longer bar and chain. Can you put any length bar on any chainsaw?

Chainsaws are designed to operate with guide bars of certain lengths and can not be used with all lengths of bars. Chainsaw manufacturers design chainsaws to operate within certain specifications that include guide bar length.

A chainsaw’s engine’s power is directly affected by the length of the guide bar on the chainsaw. Longer guide bars require more horsepower to turn than shorter guide bars. Chainsaws with smaller engines need to use smaller guide bars than chainsaws with larger engines.

Check the specifications with your chainsaw’s manufacturer to make sure the guide bar and chain you’re selecting are within the operating specifications of your chainsaw.

What are the different chainsaw bar lengths?

Chainsaw bars come in many different lengths to fit a wide range of chainsaws that have varying degrees of horsepower and other operating specifications.

Typical chainsaw bar lengths range from 12 inches to 60 inches for various chainsaw models.

There are instances where there are shorter and longer bars but they are not typical. They are more than likely used in special circumstances. Shorter than 12 inches bars are typically found on pole saws and longer than 60″ bars are used on special pieces of equipment like portable sawmills.

Can I put a 20 inch bar on a 16 inch chainsaw?

A chainsaw with a 16″ bar and chain can tackle small and medium-sized tasks in most cases. But what if you’re needing a longer bar to get the job done? Can you put a 20-inch bar on a 16-inch chainsaw?

A 16-inch chainsaw can run a 20-inch bar if it falls within the manufacturer’s specifications in the owner’s manual.

If a 20-inch bar is installed on a chainsaw and it’s outside of the specifications of the manufacturer the operation of the chainsaw will not be optimal. The chainsaw will likely not be efficient in spinning the chain while under load and your cutting experience will be negatively affected.

If a chainsaw can not carry a load of a longer guide bar, having the longer bar is pointless. In some cases when you need a longer bar you will need to purchase or borrow a chainsaw that is designed to carry the length of bar your tasks requires.

Is a 20-inch chainsaw too big?

A chainsaw’s bar length can affect whether or not certain tasks can be done quickly and efficiently. In most cases, chainsaw operators are trying to tackle large limbs and trees with an undersized chainsaw. In these instances, chainsaws with 20-inch or larger bars are needed.

But what if your cutting job is for small to medium-sized limbs and trees? Is a 20-inch chainsaw too big for small to medium-sized tasks? The answer really depends on the chainsaw’s operator and the specific job.

Chainsaws that carry 20-inch bars have larger engines and can weigh significantly more than that chainsaws that use 16-inch or small guide bars. The extra weight of the longer guide bar and larger chainsaw’s engine can really take a toll on the chainsaws operator in a very short time. Using a chainsaw is not easy work and you do not want to be carrying around a large heavy chainsaw if it’s not needed.

The takeaway to this question is that the chainsaw needs to be matched to the operator and the types of tasks they will be attempting. A bigger chainsaw is not always better.

Wrapping Up

Every chainsaw will eventually need to have its bar and chain replaced. The quickest and most accurate way of finding the information for what bar and chain you need is to look on your old bar for the information. The part number and chain specifications are normally listed there.

If you can not find the information on your old guide bar you will need to measure your guide bar from where it inserts into the chainsaw all the way to the tip of the bar. Remember to round this number to get the effective length of the bar.

Don’t forget to determine your guide bars pitch by measuring the distance of rivets on any three drive links and dividing by two.

Gauge is also vital and is obtained by measuring the width of the drive links on the chain. This number is listed in thousandths of an inch.

Lastly, but equally as important, remember to make sure that the oil ports line up between the guide bar and the chainsaw. If they do not your new guide bar and chain will not be lubricated properly and can be ruined not to mention all the bar oil that your chainsaw is wasting.

Once you have the bar’s effective length, pitch, gauge, and oil port location you should have no problem in finding the correct guide bar and chain.

Chainsaws can run a wide array of bar sizes but they do have limitations. You can not simply install any guide bar on any chainsaw and expect it to operate properly. Chainsaw manufacturers design each model of their chainsaws with specifications for guide bar size. Larger more powerful chainsaws can run longer guide bars while smaller chainsaws are more limited in bar length.

Remember to check the owner’s manual for the minimum and maximum bar length your chainsaw can handle.

Guide bars come in a wide range of lengths for chainsaws of all sizes and power. Standard bar sizes range from 12-inches all the way to 60-inches for use on regular chainsaws. Keep in mind there are bar lengths outside of the 12-inch to 60-inch range, however, they are not usually for standard chainsaw use. Uses for these bar sizes are usually for pole saws and applications like portable sawmills.

It’s very important to match the chainsaw to the operator and the kind of work they will be doing. For example, in certain situations, you may have a job that requires cleaning up large tree branches or downed trees and you will need a large, heavy, extremely powerful chainsaw. Operating a chainsaw like this is required for this type of task but it can be exhausting. If your prospective job is for smaller limbs and trees you probably will not need a chainsaw so big and powerful. In this case, it’s best to go with a smaller chainsaw and save your energy and back.

Chainsaws are great tools to get work done around the house or farm. Just remember that bigger is not always better in the world of chainsaws. Large chainsaws require more energy output from the operator because of their weight. If a small lighter chainsaw can get the job required done why not use one instead and save your back and energy.

No matter what chainsaw you decide to use always be safe. Happy cutting!